What our customers do.

And what we do for our customers.

Since the beginning of our company we have been supporting the aviation industry as a subcontractor with the production of individual parts as well as with the assembly of subassemblies and complete devices.

Since 2014, this has been underpinned by our certification to the European standard EN 9100, which provides the framework for a quality management system for organizations in the aerospace and defense industries.

Our long experience and partnerships with direct contact to our customers enable us to play a supporting role in development and manufacturing.

From prototype to production, we offer both design and manufacturing.

In our parts manufacturing department we have several CNC turning and machining centers available for machining almost any material. Process-safe and batch-managed.

The complete assembly of sophisticated assemblies and devices pass through the required test processes. After final inspection, release with acceptance test report.

For needs in this area, we carry out repairs, manufacture individual and spare parts and assemble new mechanical and electronic assemblies as well as complete devices.

Special testing devices ensure the high product requirements. We are also available to our customers as a partner in this area. An example:

One of our customers had the delivery of a monitoring device cancelled by the previous supplier, which led to a standstill in the further production chains. We were able to help with the design and manufacture of a replacement unit.

After extensive test procedures, the transmitter was approved and released for series production. Close and direct cooperation with the customer enabled short planning, development and realization times.

Mechanical engineering

Our clients manufacture, for example, portable machines as well as boom, medium and large machines for all metal cutting processes. Cutting technologies include laser, plasma, waterjet and oxyfuel.

Other customers supply packaging machines for all kinds of products, e.g. for food or chocolate, as well as components for conveyor and drive technology.

For more than 20 years we have been active as a subcontractor for machine and special machine construction, both in the production of individual parts and in the assembly of machine subassemblies.

In addition to individual parts, we supply welded constructions, assemblies and system modules to manufacturers of portable, boom, medium and large machines for all metal cutting processes in laser, plasma, waterjet and oxyfuel technology.

Precision parts are manufactured in-house according to customer drawings, required surface treatments are covered by reliable partners.

To ensure permanent delivery capability, we offer warehousing and Kanban solutions. Complete solutions, also with special requirements, can be carried out with in-house design and subsequent production. The construction of jigs and auxiliary tools is part of our offer, as well as revision and repair.

Here we fully support our customers as a partner. This is how workstations are set up according to the product.

The production of individual parts takes place in-house, and we also carry out any necessary material procurement. Approved and calibrated test equipment is used to adjust and test the assemblies. We also offer batch and serial number marking.

Special requirements for sensitive areas of measurement technology, such as explosion protection, are implemented by means of verifiable permanent tests and material subject to batch control.

Dentistry and dental technology

Our customers in the dental sector supply materials and products for dentistry, dental technology and dental hygiene.

For example, plastics and working materials for casting technology for the production of partial and total plastic dentures as well as model casting dentures.

We supply equipment, casting cells and accessories from our own development and production.

Many years of experience in this branch and in the related apparatus engineering combined with quality-conscious approach in design and production ensure robust and reliable consumer goods.

Metallography

We supply customers in the metallography industry with specialty plastics as well as equipment and processing aids for materials testing.

In metallography, metallic materials are examined using microscopic techniques. This evaluation of metal structures is widely used in quality assurance and failure analysis as well as in research and development.

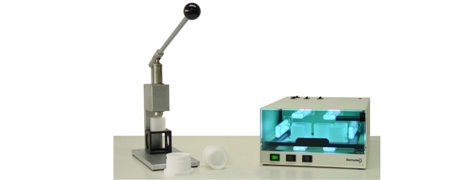

From our own development we produce UV light polymerization equipment, embedding molds made of PTFE and PP as well as sample deformers.

For embedding molds, polytetrafluoroethylene, colloquially known as Teflon, is the material with the most favorable properties. Molds made of this material retain their shape even after prolonged use.

Molds made of polypropylene have also been developed so that light-curing plastics can also be used. PP is highly permeable to UV light, has high strength and is therefore also well suited for all chemically curing embedding materials. A new lid concept allows the specimen to be embedded together with the lid without having to remove it.