Individual assemblies

Assembly is much more than just putting parts together. Assemblies offer solutions for complex and individual tasks in our customers’ applications.

We develop the necessary processes in cooperation with you. Together with your specialists, we develop solutions for the seamless integration of fully assembled assemblies into your production.

We are available both as an “extended workbench” for contract manufacturing and as a competent supplier, providing services ranging from materials planning and procurement to warehousing and commissioning.

We have long-standing business relationships with customers from a wide range of industries. This motivates us to also be your partner for precision in future developments.

We manufacture complex assemblies and components for mechanical engineering and plant construction.

Precise, fast and uncomplicated:

- Complete assembly of subassemblies – including testing and documentation

- Assemblies from the fields of mechanics, pneumatics, sensors, optics and measurement technology

- Production according to your specifications in large and small series

- Manufacturing as special, prototype, sample or individual construction

- New or further development of assemblies – including documentation

- Manufacturing of subassemblies and components

- Leak test and pressure test

- Handling and storage of ESD-hazardous components and subassemblies

- Flexible production control (Kanban)

- Laser marked to specification

- At the desired date

Precision engineering is a matter of course for us. In our precision mechanics workshop we manufacture assemblies, small devices and fine equipment.

For example, precision devices for testing and measuring tasks as well as precision control and regulating devices. For example, the handling of perforated and cover stones is one of our usual activities. 🙂

We have the necessary technology at our disposal, for example:

- Joining and pressing

- Riveting and driving rivets

- Punching and bending

- Upsetting and flanging

- Gluing and soldering

- Laser marking

- Electropneumatic wobble riveting

- Immersion and ultrasonic cleaning

You will find in us a reliable and competent partner who attaches great importance to the highest quality of assemblies.

- Tested and on time.

Mechatronics

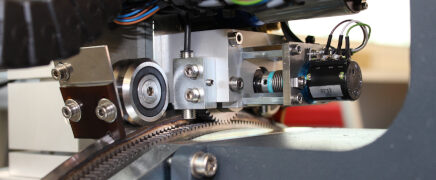

Mechatronic systems, with elements of mechanical engineering, electrical engineering and information technology, are produced in our assembly. Here there is a close interlocking with the production of system modules.

We use the term system module to describe components that consist of up to 800 individual parts and form a functional unit. This can be, for example, a sub-unit of a machine that is subjected to a final test after assembly.

The manufacture of such system modules is often subdivided into a large number of subassemblies in which the interaction of mechanical and electrical engineering plays a major role.

We offer for example:

- Installation of mechanical and electrical subassemblies and components

- Measurement and testing of mechanical and electrical quantities

- Installation and testing of hardware and software components

- Installation and testing of control systems

- Programming of mechatronic systems

- Assembly of subassemblies and components to machines and systems

- Disassembly and assembly of machines, systems and equipment

- Testing and setting of functions on mechatronic systems

- Commissioning and operation of mechatronic systems

- Repair and maintenance of mechatronic components

Cable assembly includes a wide range of different processing steps, for example:

- Cutting to length and stripping

- Stripping, crimping or tinning

- Soldering, plugging or clamping

- Insulating and protecting

Here we process different cables and systems, e.g.:

- Power lines

- Control lines

- Data cables

- Connector systems

- Cable harnesses

- Thermocouples

Our extensive manufacturing capabilities also guarantee high-end processing of single stranded, round, spiral, flat ribbon and foil cables. We assemble stranded wires from 0.06 mm² in a wide variety of designs, e.g.:

- H05V-K

- H07V-K

- High temperature stranded wires

- Teflon stranded wires

- Halogen free stranded wires

- YV wire

- Silicone cable

- Silicone free stranded wire

The stranded wires and cables can be stripped, tinned, or provided with insulated or uninsulated stop components or crimp contacts as required.

Challenge us with your wishes and additional features. Be it solutions for explosion protection, sealing solutions by potting and bonding techniques or sealing solutions for water, dust and helium as well as robust overmolding solutions.

We guarantee reliable work, first-class quality and optimal adherence to delivery dates. We not only realize standard solutions for you, but also sample construction, small series and special cable construction within a short time.